DRILLING

FOXTROT International LDC (FOXTROT), operator of Bloc CI27 Joint-Venture, is committed to contribute to Ivory Coast Energy growing needs. This ambition requires full Management involvement in order to consolidate long term production, which means drilling exploration and development wells.

Drilling Department main duties are:

– Drilling

– Completion

– Well Interventions (workover, coiled tubing, wireline, slickline)

The activity is mainly related to the Drilling campaigns that are sanctioned during Technical Committees with partners, which makes the activity quite irregular.

FOXTROT is using an Expert’s network, each of them well recognized in their domain, having an excellent knowledge of Good Oilfield Practices. From their involvement in the consecutive Drilling campaigns, they acquired a good knowledge of Bloc CI-27 to capitalize experience, know-how and have a good judgement of the risks involved.

In 2015 - 2016, FOXTROT completed an important Drilling campaign with five complex wells put on production, thus bringing the total number of producing wells to 13.

Technical challenges

During this campaign, the objectives were quite complex to achieve:

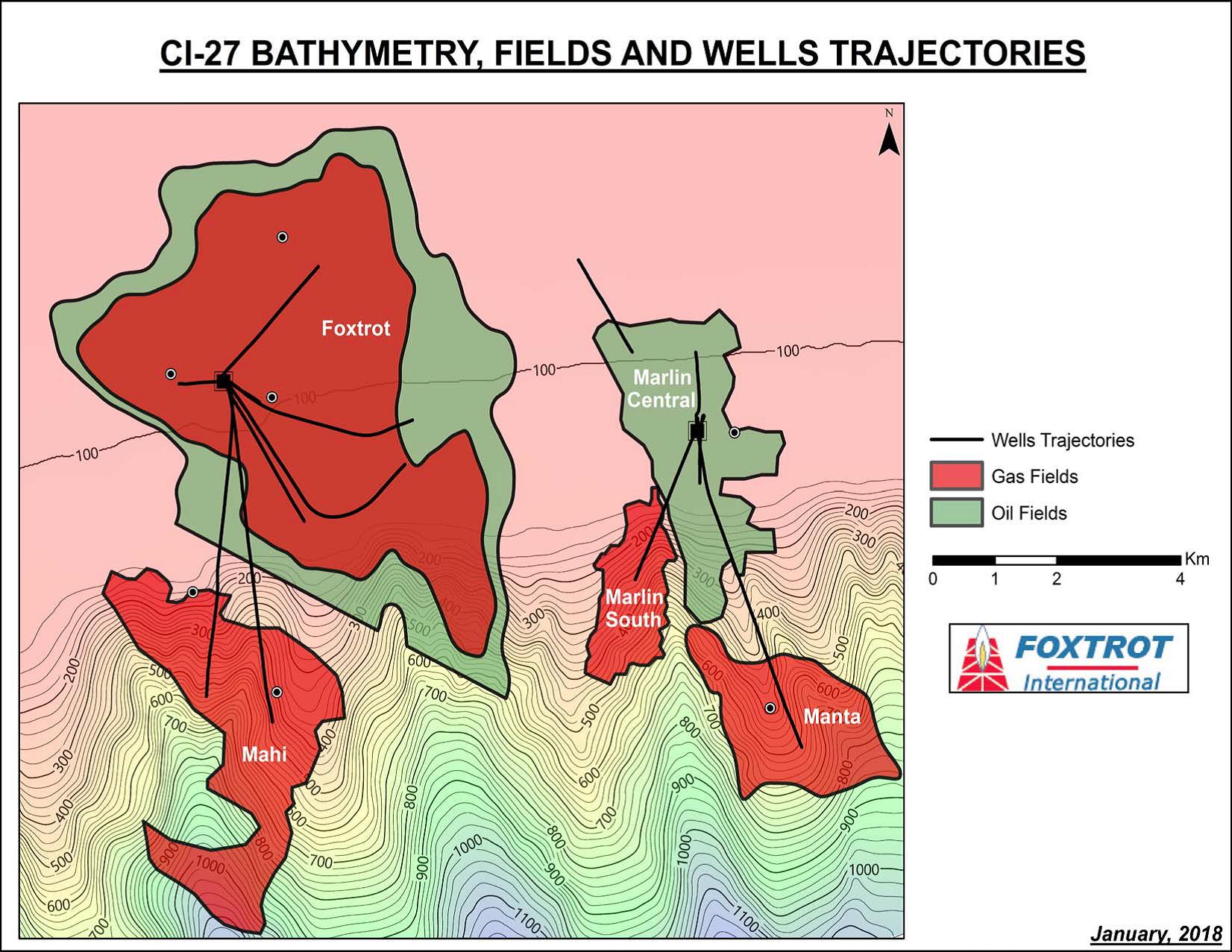

• Producing both Marlin and Manta reservoirs from the same platform generates long horizontal departures and drilled lengths as well as complex 3D profiles. Installing two platforms in water depth > 100 m was not economical;

• Manta reservoir is located in deep water below the slope of the continental shelf in soils that are increasingly weak and prone to losses due to the decreasing overburden. The combination of high inclination, drilled length and weaker fracture gradient become quite complex to manage and require special techniques;

• The oil rim in Marlin reservoir is quite thin and requires a very accurate positioning of the hole.

The operations have been carried out with a semi-sub tender drilling unit. Downhole and surface data were transmitted in real time to the base for a constant monitoring.

Each of these reservoirs required specific measures, that were very different from one well to the other.

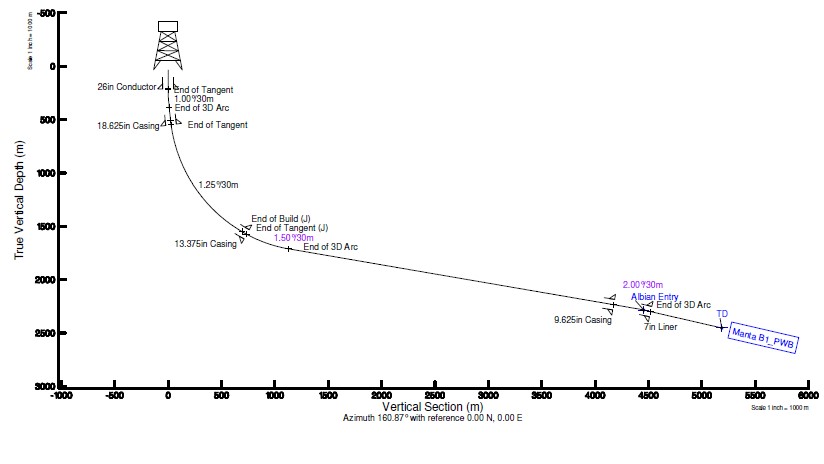

Reaching Manta reservoir entailed extended well drilling techniques.

| Target departure : 5 km |

| Target located in deepwater |

| Weak formations due to the low overburden |

| Crossing faults |

| Very small target compared to the drilled length |

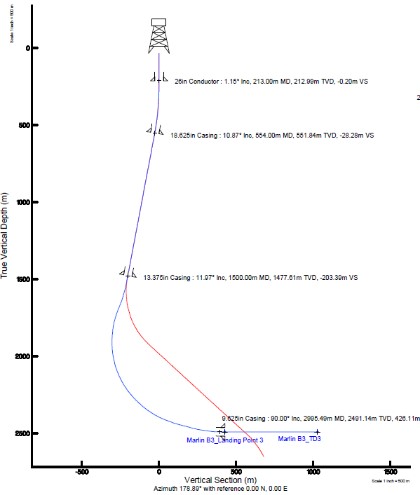

The oil rim in Marlin reservoir led to choose horizontal drains technique. The small thickness required very accurate positioning of the landing depth and geo-steering through the drain.

| TUnconsolidated reservoirs requiring sand control |

| Small oil thickness |

| Pilot hole prior to side-track and landing the horizontal drain at a very accurate depth |

| Horizontal drilling and geosteering |

Use of the latest technologies

To cope with these challenges, some of the latest techniques have been implemented. In close cooperation with its Contractors and its Expert’s network, Foxtrot chose the following technologies.

"In-Field Referencing" technology

Measurement of the local magnetic field in order to improve the well trajectory and be able to hit a small target at drilled lengths > 6000 m.

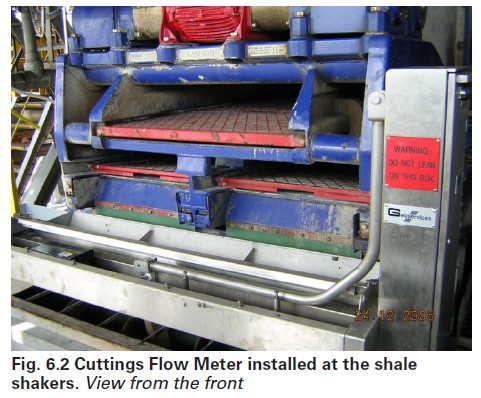

"Hole cleaning Cuttings flow meter" technology

Cutting returns measurement to be able to spot hole cleaning anomalies as early as possible in long and highly deviated wells

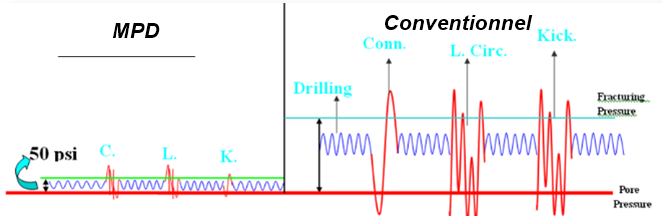

"Managed Pressure Drilling" (MPD) technologies

MPD technology uses a rotating Blow Out Preventer and a choke system driven in real time by downhole pressure measurement in order to keep a constant downhole pressure and avoid hole sloughing or losses.

"rotary steerable" downhole motor

This technology allows a very good trajectory control that is managed from the surface, based on downhole information (ie formation or fluids detection) in order to optimize hole placement in a thin oil reservoir.

Combined with the pilot hole correlation, the vertical accuracy is in the range of 10 cm.

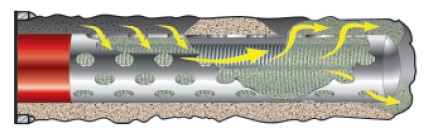

"Gravel pack alternative path" used in horizontal drains in unconsolidated formations

Gravel is pumped and placed between the reservoir and the screens to prevent sand production. This technology has the advantages to be rather simple to implement and to be more robust than alternative solutions.

These technologies allowed to reach the five wells objectives in time and budget.